Industrial Hot Air Blower

Hot Air Blower

Industrial-grade hot air blower designed for efficient heating, drying, and surface treatment. Delivers controlled hot air up to 200°C with uniform airflow. Ideal for packaging, textile, plastic, and process industries. Available in various capacities from 3KW to 40KW with digital temperature control.

- Description

Description

Hot Air Blower – Industrial Grade

Our Hot Air Blowers are specially designed for continuous and high-efficiency hot air delivery in various industrial applications such as drying, heating, shrinking, curing, and surface treatment.

Key Features:

-

Heating Capacity: Available in 3KW to 50KW or custom as per requirement

-

Air Flow (CFM): Ranges from 100 to 1000+ CFM

-

Temperature Range: Up to 200°C (Adjustable)

-

Motor: High-performance TEFC motor (0.5 HP to 5 HP)

-

RPM: 1440/2800 RPM as per design

-

Construction: MS / SS body with high-temperature insulation

-

Control Panel: Optional digital temperature controller with thermostat

-

Mounting: Portable or fixed as per usage

Applications:

-

Plastic industries

-

Textile drying

-

Powder coating and paint booths

-

Food processing

-

Paper and printing industries

-

Pharma & packaging

Advantages:

-

Uniform and targeted heating

-

Low maintenance

-

Energy-efficient design

-

Compact and robust build

�� 40 kW Industrial Hot Air Blower with Digital Control Panel ��

✅ Heating Power: 40 kW

✅ Blower Motor: 3 HP, 1440 RPM

✅ Airflow: Approx. 3000–3500 CFM (customizable)

✅ Temperature Range: Ambient to 200°C

✅ Power Supply: 3 Phase, 415V / 50Hz

✅ Control Panel: Digital PID controller with temperature sensor

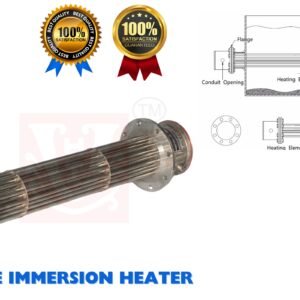

✅ Heater Type: High-efficiency SS tubular heaters

✅ Safety Features: Over-temperature protection, MCB, contactor-based safety circuit

✅ Application Areas:

- Paint booth drying

- Pharmaceutical & food drying

- Textile and paper drying

- Plastic, rubber, and auto component heating

- Preheating chambers

�� Key Features:

- Uniform heat distribution

- Heavy-duty construction

- Easy installation & low maintenance

- Energy efficient

- Custom air outlet size available

�� Optional Add-ons:

- Flexible ducting

- Wheels for portability

-

🛠️ Maintenance Schedule

Task Frequency Details Check air inlet & outlet Weekly Remove any dust or obstruction Clean blower and heater housing Monthly Use air jet or dry cloth Inspect motor bearings Quarterly Apply grease/lubricant if required Electrical connection check Monthly Tighten terminals, check for heat marks Inspect heater elements Every 6 months Check for cracks, hotspots, or discoloration Calibrate temperature controller Every 3–6 months Ensure accurate temp control Safety components test Quarterly Test thermostat, MCB, overload relay

⚠️ Safety Tips

-

Never operate without airflow — it may damage the heater.

-

Always switch off power before maintenance.

-

Use only genuine spare parts and approved accessories.

-

In case of abnormal temperature rise, shut down immediately and inspect.

-